Service purposes of our fire pumps

A fire pump is an essential component for protecting a building or a place against fire accidents. The fire pumps are designed to quickly deliver a sufficient amount of water to protect against fire accidents. The fire pumps are usually connected to the underground public water supply piping or with a tank or reservoir to supply a large amount of water when required. In higher buildings, fire pumps distribute water through the sprinkler systems where the water pressure from water mains and fire-fighting equipment cannot reach. Fire pump UL listed allows the manufacturers to make the products.

Working procedure of different types of the fire pump

A fire pump is an important part of a sprinkler system because it provides high-pressure water accessibility to the sprinkler system to increase the water flow rate. A fire pump is of customary types such as horizontal split case, vertical split case, vertical inline, and vertical turbine.

01

01

Horizontal Split Case

This is a common type of fire pump which are applicable for a higher flow of water. This is usually used in higher buildings, and these pumps are even easily accessible. The maintenance and repairs are not even a burden. They can be easily done. Due to its lifespan and availability of different sizes, it makes them even more popular among customers.

02

02

Vertical Split Case

This type is similar to the horizontal split type, but it takes less space due to the design, which is vertical. It even protects the pump from damage like potential flooding damage.

03

03

Vertical Turbine

This pump is a centrifugal pump for vertical installation. This pump is further divided into types such as oil-lubricated enclosed line shaft and water-lubricated open line-shaft pumps. Both of the types are better for various applications.

04

04

Vertical In Line

Vertical in line is a single-stage centrifugal pump designed for vertical installation. This pump provides a smooth and firm flow of water throughout the system with suction and inline delivery. The pump is not needed to be removed for repairs and maintenance because of its design.

Installation and Maintenance

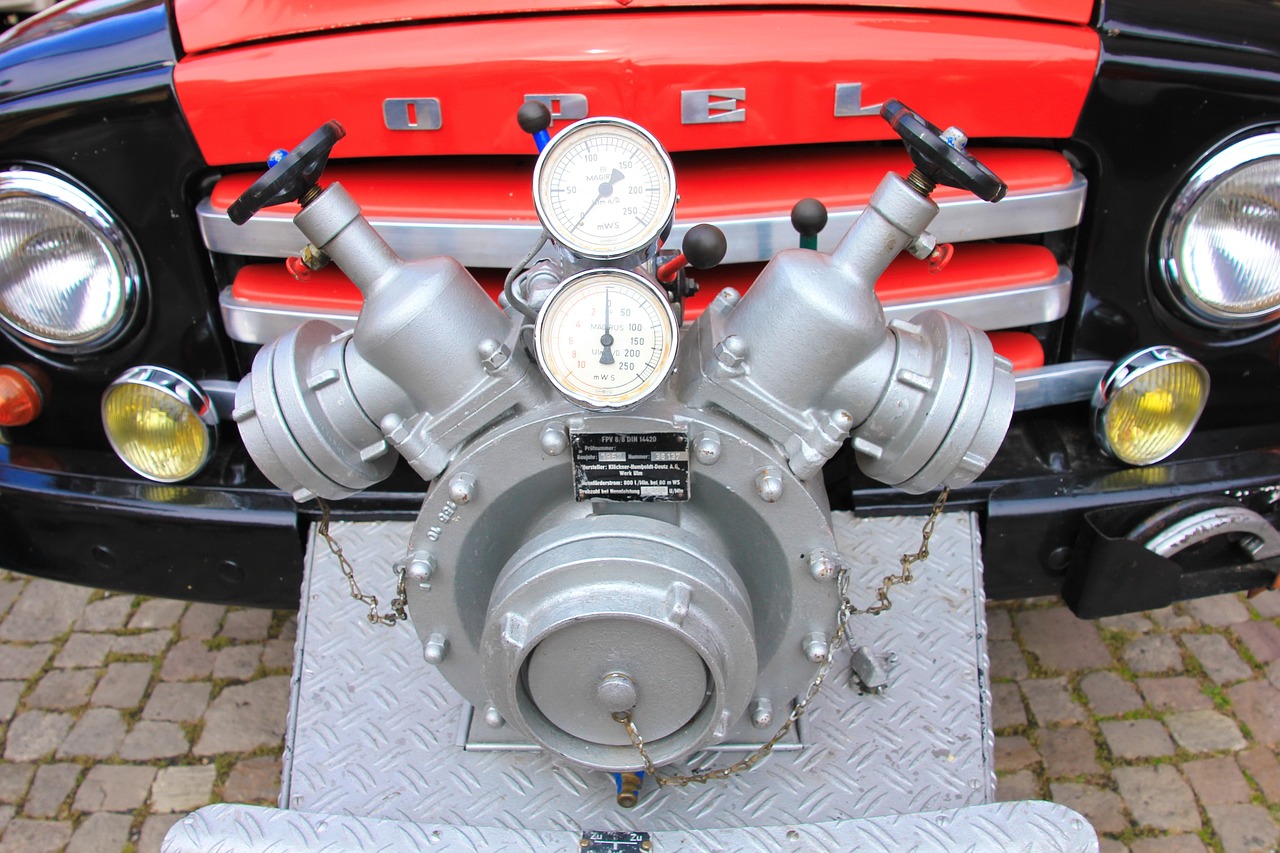

Installation of fire pumps is done carefully with all required procedures for the successful working of the system. Certified permission must be issued before installing the fire pumps, and the location of the fire pump installation should be pre-planned. The fire pump UL listed is well maintained and installed under supervision. The rooms where fire pumps are installed should be free from storage equipment and other penetration, which may not be essential for operating the pump. It must be sized properly to fit all necessary components to operate the pump well. Proper orientation is required to the suction piping to ensure minimum distance. A door must be provided to the pump installation room with a passageway to remove equipment and a properly ventilated room with heat not less than 40 degrees Fahrenheit. Daily maintenance is required for fire pumps; they must be checked every week to note their function and working procedure. For seamless operation and automatic starting, check the components frequently, and it is better to monitor the water pressure gauge of the fire pumping system.

Fire pump non-UL, Dubai are not recommended for the manufacturers to provide their service. To get the best fire pump UL listed, browse our website.